Sistemụ ndozi maka Laser Brazing

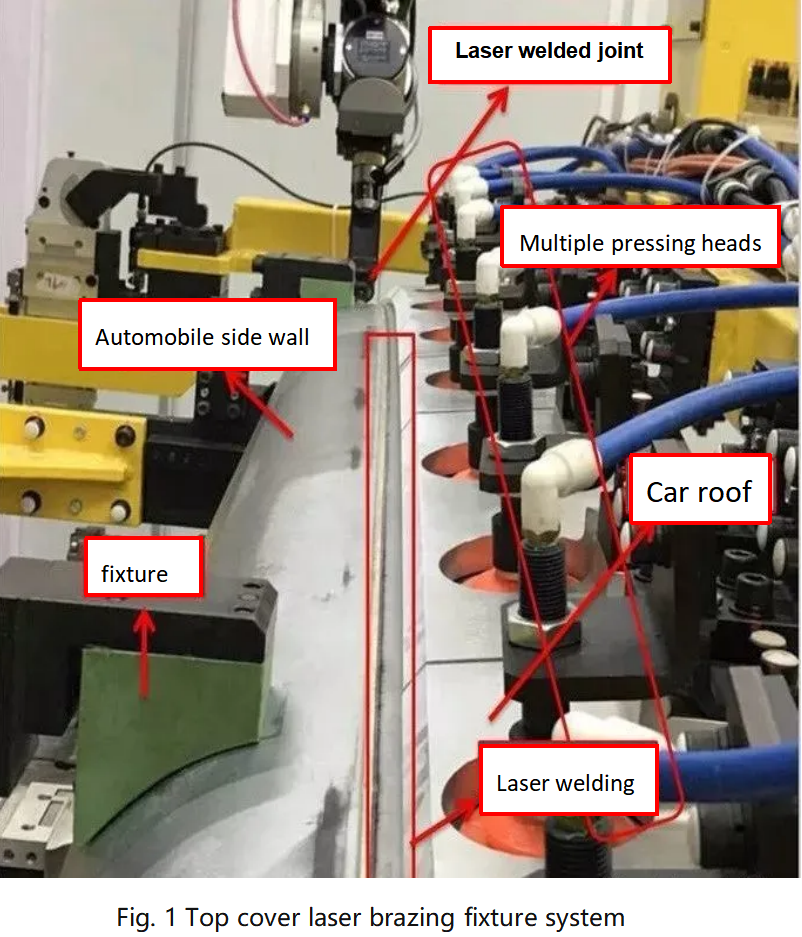

N'oge ịgbado ọkụ laser, ọ dị mkpa ịkwanye efere ígwè welded nke ọma, ya mere a ga-emepụta clamps pụrụ iche.Igwe ịgbado ọkụ laser nwere nnukwu olu na usoro dị mgbagwoju anya.Ọ bụ ihe owuwu etiti n'ozuzu ya.A na-akwado akụkụ aka ekpe na aka nri nke ahụ ụgbọ ala site na ihe mgbochi na-ejikọta ya na cylinders mgbe edobere na nkwado.A na-emepụta akụkụ nke elu ya na ntinye pụrụ iche na ịpị gripper maka laser brazing nke ụlọ ụgbọ ala, nke a na-eji ọtụtụ isi isi.Robot ahụ na-ejide elu ụlọ ahụ, tinye ya n’ahụ́, ma jiri ígwè silinda kụchie ya, nke mere na akụkụ nke efere ahụ a ga-eji welding dabara adaba nke ọma.Dị ka e gosiri na foto 1.

Usoro ihe

• · Okpomọkụ

• · N'akụkụ ihe omume nke ọkụ laser

• · Mkpokọta na defocus

• · penetration omimi nke ịgbado ọkụ

• · Mmetụta nke ịgbado ọkụ ọsọ na laser ịgbado ọkụ ike

Nwalee

•, Nleba anya

• · Dị ka ọkọlọtọ German PV 6917 (nwere ike nweta site na ịkpọtụrụ onye edemede);

• · A ga-eme nleba anya n'anya maka nzụkọ nke ọ bụla na-anọghị n'ahịrị;

• Lekwasị anya na nchọpụta nke ntinye weld (dị ka ntinye na-ezughị ezu, n'elu ntinye na ọkụ), ma buru n'uche ọnọdụ elu nke weld (dị ka spatter na porosity);

E gosipụtara usoro nleba anya nke nlele laser brazing na tebụl 1.

| Tebụl 1 Nleba Ogo Ọdịdị nke Laser Brazing | ||

| Oghere Usoro No | Nkọwa ntụpọ | Ntụle adịghị mma |

| 1 | pores ekpughere | Ọ bụrụ na ọnọdụ kwenye, enwere ike ịrụzi elu ma ọ bụrụhaala na ọ naghị emetụta ọrụ ahụ;A ghaghị ịrụzi oghere ikuku nwere dayameta karịa 0.2mm |

| 2 | Njubigara ihe na-ere ere (oke) | Ọ bụrụ na ọnọdụ kwenye, enwere ike ịrụzi elu ma ọ bụrụhaala na ọ naghị emetụta ọrụ ahụ;Enwere ike ịrụzi ya |

| 3 | Layer ripple na weld elu | The nkwonkwo ga-ejupụta na solder nọgidere;Enwere ike ịrụzi ya |

| 4 | Mgbawa elu (transverse na longitudinal) na-eme na weld | Ọ bụrụ na ọnọdụ kwenye, enwere ike ịrụzi elu ma ọ bụrụhaala na ọ naghị emetụta ọrụ ahụ;Enwere ike ịrụzi ya |

| 5 | Mgbawa dị n'elu (transverse na longitudinal) na-eme na metal ntọala | Erughị eru, chọrọ nrụzi |

| 6 | Isi ntinye ígwè | Erughị eru, chọrọ nrụzi |

| 7 | Akpụchapụrụ na ntinye ezughị ezu | Erughị eru, chọrọ nrụzi |

| 8 | ọsụsọ | Ọ bụrụ na ọnọdụ kwenye, enwere ike ịrụzi elu ma ọ bụrụhaala na ọ naghị emetụta ọrụ ahụ;Enwere ike ịrụzi ya |

| 9 | Enweghị anụ | Ekweghị, nrụzi chọrọ |

| 10 | A naghị agbado njedebe mmalite, a na-agbanyekwa ọnụ ọnụ | Ekweghị, nrụzi chọrọ |

| 11 | Weld na-efu (nnukwu oghere dakọtara) | Ekweghị, nrụzi chọrọ |

2, nyocha na-emebi emebi

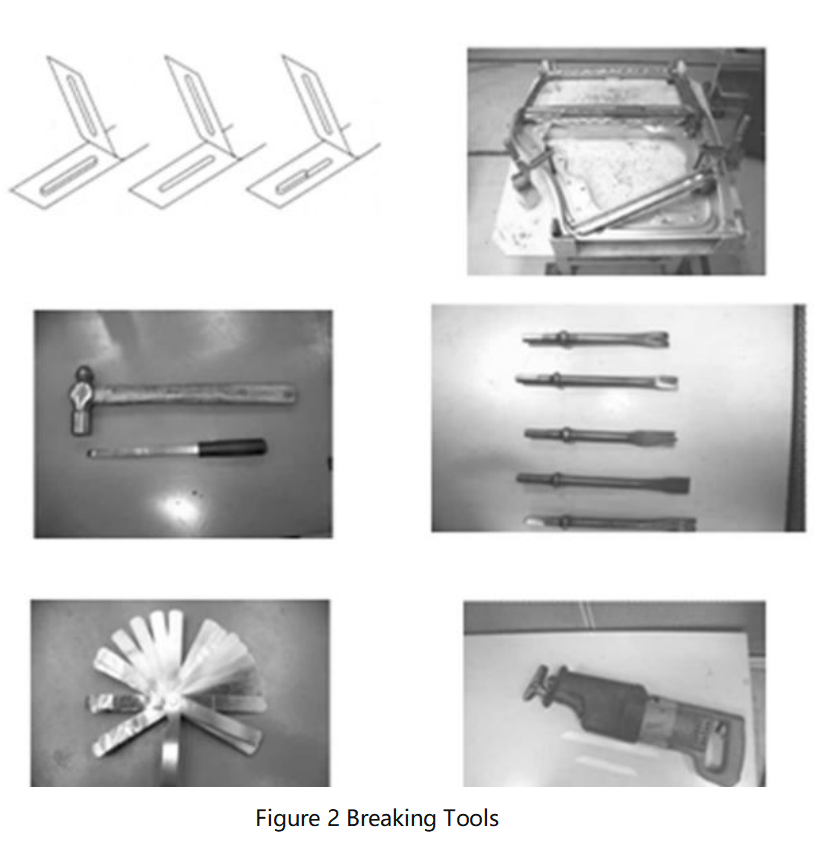

E gosipụtara ngwaọrụ nleba anya nbibi na eserese 2:

3 、 Metallographic microscopic Analysis

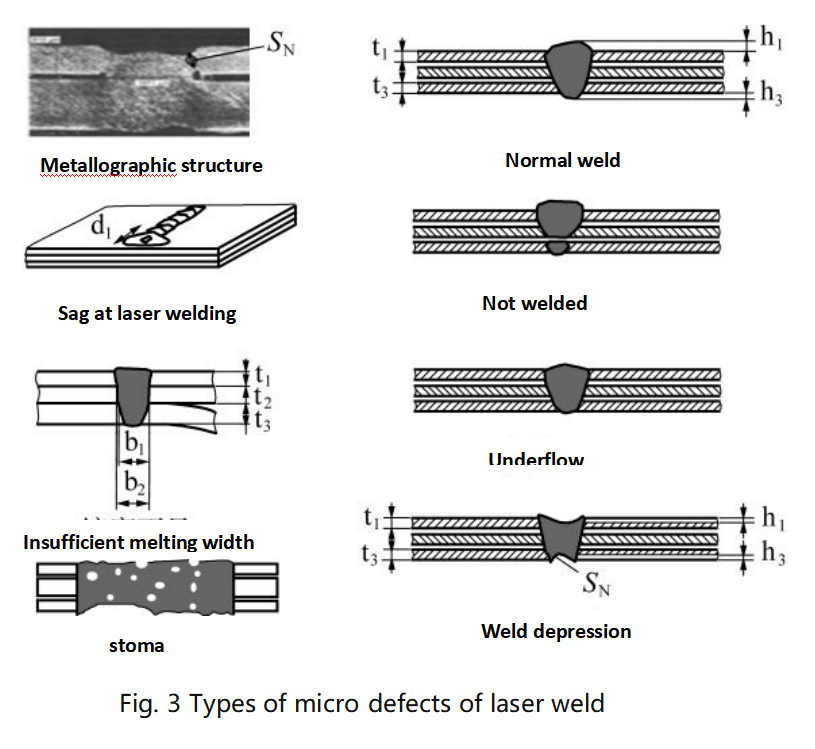

E gosipụtara ụdị ntụpọ micro nke weld laser na foto 3:

4, NDT

Enwere ike iji Ultrasonic, X-ray na ngwa ndị ọzọ nyochaa ogo ịgbado ọkụ laser.

Nchịkọta

Dị ka n'ezie ngwa mmetụta nke laser ịgbado ọkụ technology na ụgbọ ala osisi, ọ pụrụ ịhụ na laser ịgbado ọkụ nwere ike ọ bụghị nanị ibelata arọ nke ahụ ụgbọ, melite nzukọ ziri ezi nke ụgbọ ahụ, kamakwa ukwuu welie ike nke ụgbọ. ahụ, na-enye ndị ọrụ nchebe ka mma mgbe ha na-enwe nkasi obi.A kwenyere na na ọganihu na-aga n'ihu nke nsogbu teknụzụ ịgbado ọkụ laser na ọganihu na-aga n'ihu nke usoro mmepụta ihe, ịgbado ọkụ laser ga-abụ akụkụ dị mkpa nke ahụ ụgbọ ala n'ọdịnihu na usoro mmepụta ọcha.

Oge nzipu: Jan-09-2023