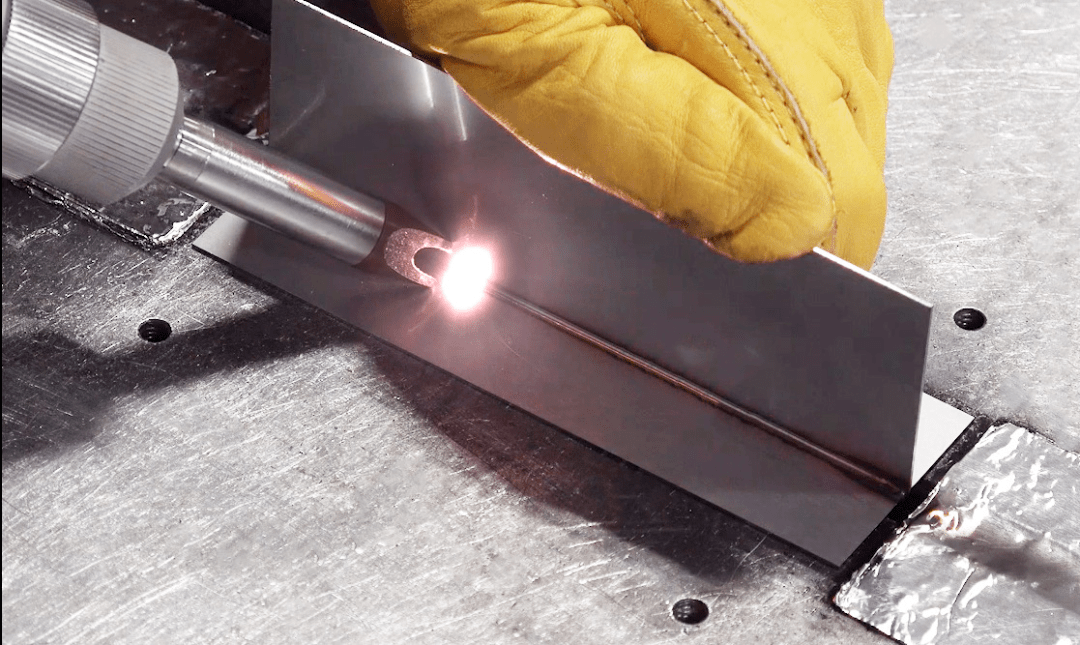

Dị ka onye ọ bụla nọ na gburugburu ịgbado ọkụ si mara, MIG ịgbado ọkụ na TIG ịgbado ọkụ na-ọtụtụ ebe na ụlọ ọrụ.Agbanyeghị, ụzọ ịgbado ọkụ abụọ a nwere nnukwu ihe achọrọ maka nka nke welders.Welders kwesịrị itinye oge dị ukwuu iji mụta ihe dị mkpa ịgbado ọkụ.Sistemụ ịgbado ọkụ nke ejiri aka laser na-eme ka ọ dịrị ndị nkịtị mfe ịmalite, ma nwee ike nweta mmetụta ịgbado ọkụ dị elu ngwa ngwa.

Anyị emeela ọtụtụ ule arụmọrụ na ụdị ịgbado ọkụ nke laser handheld welding, dị ka esemokwu, ịgbagọ, na metallography.Ọzọ, ka anyị hụ ma àgwà ịgbado ọkụ nke sistemu ịgbado ọkụ laser ejiri aka nwere ike ịgafe ule ahụ nke ọma.

01, Atụmatụ

• Ike laser ruru 1500W.Maka ihe dị iche iche na ọkpụrụkpụ, ntọala ịgbado ọkụ kachasị mma nwere ike ịhọrọ ngwa ngwa site na mkpịsị ugodi mgbanwe.

• Jiri 74 echekwara preset na onye ọrụ-akọwapụta usoro parameters aka novice welders ịmụta ịgbado ọkụ ọrụ site ọtụtụ awa nke ọzụzụ.

• Họrọ ọnọdụ nchekwa iji nye ike kacha elu ruru 2500W, iji nwee ike ịgbado ọkụ siri ike.

• A na-agbakwunye ọrụ nhicha ọhụrụ na ntọala mbụ, nke nwere ike wepụ mmanụ, nchara, na mkpuchi ngwa ngwa ngwa ngwa tupu ịgbado ọkụ, ma wepụ ihe ndị dị n'elu na oxidation discoloration mgbe ịgbado ọkụ.Enwere ike nweta weld mara mma na-enweghị iji abrasives ma ọ bụ kemịkalụ, na-azọpụtakwu ụgwọ na oge.

02, Weldable ihe

| Sayensị ihe onwunwe | ỌkpụrụkpụOtu akụkụ weld | ỌkpụrụkpụWeld akụkụ abụọ |

| igwe anaghị agba nchara | 4mm | 10mm |

| ígwè dị nro | 4mm | 10mm |

| aluminom | 4mm | 10mm |

| ọla kọpa | 1mm | 2mm |

03, Uru

• High ịgbado ọkụ: 4 ugboro ngwa ngwa karịa omenala ịgbado ọkụ, na-amụba arụpụtaghị ihe na mbenata na-eri nke ọ bụla workpiece.

• Akwa ịgbado ọkụ àgwà: Uniformly welded oké ihe, mkpa ihe, na-egosipụta ọla na-enweghị deformation, undercut, ma ọ bụ ọkụ-site na, na okpomọkụ-emetụta dị nnọọ obere.

• Ọ dị mfe iji: Ntọala dị mfe, mmụta, na ịrụ ọrụ na ịda mbà n'obi, nwere ike ịghọta ụdị ịgbado ọkụ na nhicha dị elu.

• Ọdịdị Weld: A ga-ewepụ ntụpọ mmanụ, nchara, na mkpuchi tupu ịgbado ọkụ, a ga-ewepụkwa ihe fọdụrụ n'elu na oxidation discoloration mgbe ịgbado ọkụ, na-echekwa oge na ego nke iji abrasives ma ọ bụ kemịkalụ.

• Ihe dị iche iche nke ihe dị iche iche: ọla dị iche iche dị iche iche, akụkụ dị oke mkpa, ịgbado ọkụ ọla kọpa, na ihe dị iche iche conductivity.

• Ịgbado ọkụ na-agbado: Obosara swing bụ ruo 5mm, na-eme ka ike ịgbado ọkụ na ịdị elu weld mara mma.

• Nchekwa ndị na-arụ ọrụ: Sensọ multistage na ngwaọrụ nchekwa njikọ

| Usoro ịgbado ọkụ ọdịnala | Mgbado ọkụ laser | |

| ịgbado ọkụ ọsọ | nkịtị | Kariri ugboro anọ ngwa ngwa |

| ịgbado ọkụ àgwà | Dabere na ahụmịhe onye ọrụ | Mmetụta dị elu dị elu |

| Ịmụ ihe siri ike | ike | Ọ dị mfe iji |

| Nkwadebe maka ịgbado ọkụ workpiece | Nkwadebe dị mkpa na nsogbu | Nkwadebe dị obere ma dị mfe |

| Workpiece nkwadebe tupu ịgbado ọkụ ihe mgbanwe | Oke site na mgbanwe ihe onwunwe | Ogologo oke, enweghị mkpa ịtọ |

| Mpaghara okpomọkụ metụtara | nnukwu | Obere |

| Ehulata na nrụrụ | Ọ dị mfe imebi | Ọ dịghị mfe deform |

| Mgbado ọkụ ọkụ | Ọ dịghị | Obosara swing ruo 5mm |

04. Nka na ụzụ parameters

| ike laser | Ike kacha elu | ike | Ikike nchekwa ọnọdụ | obosara nhichana ogologo | Ogologo swingna ugboro ole | Akụkụ(L*W*H) | ibu |

| 1500W | 2500W | 220V,24A | 74 | 15mm | Ruo 300H,ruo 5mm | 641*316*534mm | 53KG |

Anyị nwere ike ịhụ na arụmọrụ nke ịgbado ọkụ ejiri aka laser dị elu karịa ịgbado ọkụ TIG ọdịnala na ịgbado ọkụ MIG n'ọtụtụ akụkụ.Ikekwe n'oge na-adịghị, ubi ịgbado ọkụ ga-abụ ụwa nke laser aka-ẹkenịmde ịgbado ọkụ.

Oge nzipu: Nov-30-2022