Laser n'elu ọgwụgwọ bụ a nkà na ụzụ na-eji elu ike njupụta laser doo ikpo ihe onwunwe n'elu a na-abụghị kọntaktị ụzọ, na-aghọta ya n'elu mgbanwe site conductive jụrụ nke elu ihe n'onwe ya.Ọ bara uru iji meziwanye ihe eji arụ ọrụ na nke anụ ahụ nke elu ihe ahụ, yana ihe mgbochi na-eyi, nkwụsị corrosion na ike ọgwụgwụ nke akụkụ ahụ.N'ime afọ ndị na-adịbeghị anya, teknụzụ ọgwụgwọ laser dị ka nhicha laser, nkwụsị nke laser, alloy laser, ike ọkụ laser na annealing laser, yana mkpuchi laser, mbipụta 3D laser, electroplating laser na teknụzụ ndị ọzọ na-emepụta ihe na-emepụta laser ebutewo atụmanya ngwa ngwa. .

1. Laser nhicha

Laser ihicha bụ ngwa ngwa na-emepe emepe ọhụrụ n'elu technology technology, nke na-eji elu-ike pulse laser doo irradiate n'elu nke workpiece, nke mere na unyi, ahụ ma ọ bụ mkpuchi n'elu nwere ike evaporation ma ọ bụ gbasaa ozugbo, si otú nweta usoro nke ihicha. na ime ka ọ dị ọcha.A na-ekewa ihicha laser na mwepụ nke nchara, mwepụ mmanụ, iwepụ agba, iwepụ mkpuchi na usoro ndị ọzọ;A na-ejikarị ya eme ihe maka nhicha ígwè, ihe ndị omenala ihicha, ihe owuwu ụlọ, wdg Dabere na ọrụ ya zuru oke, nhazi nke ọma na nke na-agbanwe agbanwe, arụmọrụ dị elu na nchekwa ike, nchebe gburugburu ebe obibi ndụ ndụ, ọ dịghị mmebi nke mkpụrụ, ọgụgụ isi, ịdị mma ihicha. nchekwa, ngwa ngwa na njirimara ndị ọzọ na uru, ọ na-aghọwanye ewu ewu na mpaghara mmepụta ihe dị iche iche.

E jiri ya tụnyere usoro ihicha ọdịnala dị ka ihicha esemokwu n'ibu, kemịkalụ corrosion ihicha, ihicha mmiri siri ike dị ike, nhicha ultrasonic dị elu, nhicha laser nwere uru doro anya.

2. Laser quenching

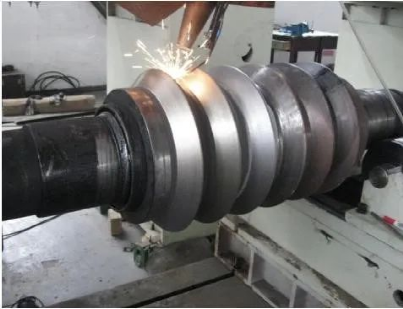

Laser quenching na-eji laser ike dị elu dị ka isi iyi ọkụ na-eme ka elu igwe na-ekpo ọkụ na oyi ngwa ngwa.A na-emecha usoro nkwụsịtụ ozugbo iji nweta ike siri ike na nhazi martensite dị oke mma, meziwanye ike ike na iyi nguzogide nke elu igwe, ma na-etolite nrụgide nrụgide n'elu iji melite nguzogide ike ọgwụgwụ.Uru ndị bụ isi nke usoro a gụnyere obere mpaghara okpomọkụ emetụtara, obere nrụrụ, ogo akpaaka dị elu, mgbanwe dị mma nke imenyụ nhọrọ, ike siri ike nke ọka a nụchara anụcha, na nchebe gburugburu ebe obibi nwere ọgụgụ isi.Dịka ọmụmaatụ, enwere ike gbanwee ntụpọ laser iji mebie ọnọdụ obosara ọ bụla;Nke abuo, laser isi na multi axis robot njikọ nwere ike menyụọ ebe a họpụtara nke akụkụ dị mgbagwoju anya.Dị ka ihe atụ ọzọ, laser quenching na-ekpo ọkụ nke ukwuu na ngwa ngwa, na nkwụsị nrụgide na nrụrụ dị ntakịrị.The deformation nke workpiece tupu na mgbe laser quenching nwere ike fọrọ nke nta ileghara, n'ihi ya, ọ bụ karịsịa adabara n'elu ọgwụgwọ nke akụkụ na elu nkenke chọrọ.

Ka ọ dị ugbu a, a na-etinye laser quenching nke ọma n'elu ike nke akụkụ ndị na-adịghị ike na ụlọ ọrụ ụgbọ ala, ụlọ ọrụ ebu, ngwá ọrụ ngwaike na ụlọ ọrụ igwe, karịsịa n'ịkwalite ndụ ọrụ nke akụkụ ndị na-adịghị ike dị ka gia, ogwe elu, ntụziaka, agba na agba. ebu.Ihe e ji mara laser quenching bụ ndị a:

(1) Laser quenching bụ usoro ikpo ọkụ ngwa ngwa na usoro obi ụtọ nke onwe ya, nke na-adịghị achọ nchekwa ọkụ ọkụ na nkwụsị oyi.Ọ bụ a mmetọ-free, akwụkwọ ndụ akwụkwọ ndụ na gburugburu ebe obibi-enyi na enyi usoro ọgwụgwọ okpomọkụ, na ike mfe mejuputa edo quenching n'elu nke nnukwu ebu;

(2) Dị ka laser kpo oku ọsọ bụ ngwa ngwa, okpomọkụ emetụta mpaghara bụ obere, na elu scanning kpo oku quenching, ya bụ, ozugbo mpaghara kpo oku quenching, deformation nke mesoo anwụ dị nnọọ obere;

(3) N'ihi na obere divergence n'akuku nke laser doo, ọ nwere ezi directivity, na ike n'ụzọ ziri ezi na mpaghara menyụọ ebu elu site ìhè ndu usoro;

(4) Omimi oyi akwa siri ike nke nkwụsị elu laser bụ n'ozuzu 0.3-1.5 mm.

3. Laser annealing

Ngwunye laser bụ usoro ọgwụgwọ okpomọkụ nke na-eji laser mee ihe na-ekpo ọkụ n'elu ihe, na-ekpughe ihe ahụ na okpomọkụ dị elu ruo ogologo oge, wee jiri nwayọọ nwayọọ mee ka ọ dị jụụ.Ebumnuche bụ isi nke usoro a bụ ịhapụ nrụgide, mụbaa ductility na ihe siri ike, na ịmepụta microstructure pụrụ iche.A na-akọwa ya site n'ikike imezi ihe nhazi nke matriks, belata ike, nụchaa ọka ma wepụ nchekasị n'ime.N'ime afọ ndị na-adịbeghị anya, teknụzụ annealing laser aghọwo usoro ọhụrụ na ụlọ ọrụ nhazi semiconductor, nke nwere ike imeziwanye njikọ nke sekit jikọtara ọnụ.

4. Laser ujo ike

Teknụzụ na-ewusi ike nke Laser bụ teknụzụ ọhụụ na nke dị elu nke na-eji ikuku ujo plasma na-emepụta site na beam laser siri ike iji meziwanye ike ọgwụgwụ, iyi nguzogide na nguzogide corrosion nke ihe igwe.Ọ nwere ọtụtụ uru pụtara ìhè, dị ka enweghị mpaghara okpomọkụ emetụtara, nrụpụta ike dị elu, oke nsogbu dị elu, njikwa siri ike na mmetụta ike dị ịrịba ama.N'otu oge ahụ, ike na-ama jijiji laser nwere njirimara nke nrụgide nrụgide mgbagwoju anya miri emi, microstructure ka mma na iguzosi ike n'ezi ihe elu, nkwụsi ike ọkụ ka mma na ogologo ndụ.N'ime afọ ndị na-adịbeghị anya, nkà na ụzụ a enwetawo mmepe ngwa ngwa, ma nwee nnukwu ọrụ na mbara igwe, nchebe mba na ụlọ ọrụ agha na mpaghara ndị ọzọ.Tụkwasị na nke ahụ, a na-ejikarị mkpuchi ahụ kpuchido workpiece site na ọkụ laser ma welie absorption nke ike laser.Ka ọ dị ugbu a, ihe mkpuchi a na-ejikarị eme ihe bụ agba ojii na foil aluminum.

Laser peening (LP), nke a makwaara dị ka laser shock peening (LSP), bụ usoro etinyere n'ọhịa nke injinia elu, ya bụ, iji ogwe ọkụ laser pulsed dị elu iji mepụta nrụgide fọdụrụ na ihe iji melite nguzogide eyi. (dị ka iyi nguzogide na ike ọgwụgwụ) nke ihe na-ebupụta ihe, ma ọ bụ imeziwanye ike nke akụkụ ihe ndị dị mkpa iji kwalite isi ike nke ihe.

N'adịghị ka ọtụtụ ngwa nhazi ihe, LSP adịghị eji ike laser maka ọgwụgwọ okpomọkụ iji nweta mmetụta a chọrọ, ma na-eji mmetụta beam maka nhazi nhazi.A na-eji ọkụ laser dị elu mee ihe na-emetụta elu nke ihe a na-achọsi ike na-arụ ọrụ nke nwere ike dị mkpụmkpụ mkpụmkpụ.

Ìhè ọkụ ahụ na-emetụta ihe arụ ọrụ ígwè ahụ, na-eme ka ihe arụ ọrụ ahụ banye n'ọnọdụ plasma dị gịrịgịrị ozugbo, ma tinye nrụgide ujo na-arụ ọrụ.Mgbe ụfọdụ, a na-agbakwunye ihe mkpuchi opaque na-arụ ọrụ iji dochie evaporation metal.Iji nweta nrụgide, a na-eji ihe mkpuchi mkpuchi ndị ọzọ ma ọ bụ nnyonye anya inertial iji weghara plasma (na-abụkarị mmiri).

Plasma na-emepụta mmetụta ujo ebili mmiri, na-emegharị microstructure elu nke workpiece na ebe mmetụta, wee mepụta mmeghachi omume n'agbụ nke mgbasawanye na mkpakọ metal.Mmetụta nrụgide miri emi nke mmeghachi omume a na-eme nwere ike ịgbatị ndụ nke akụkụ ahụ.

5. Laser alloying

Laser alloying bụ teknụzụ mgbanwe elu ọhụrụ, nke enwere ike iji kwadebe amorphous nanocrystalline mesiri cermet mkpuchi ihe mejupụtara n'elu akụkụ akụkụ dị iche iche dị ka ọnọdụ ọrụ dị iche iche nke ihe ụgbọ elu si dị na njirimara nke nnukwu ike njupụta laser beam kpo oku na ọnụego condensation, yabụ. iji nweta ebumnuche nke ngbanwe elu nke ihe ụgbọ elu.Tụnyere laser alloying technology, laser cladding technology nwere àgwà nke obere dilution ruru nke mkpụrụ ka a wụrụ awụ ọdọ mmiri, obere okpomọkụ emetụtara mpaghara, obere thermal deformation nke workpiece na obere scrap ọnụego nke workpiece mgbe laser cladding ọgwụgwọ.Ihe mkpuchi laser nwere ike imeziwanye ihe ndị dị n'elu, ma rụkwaa ihe ndị eyitere.Ọ nwere njirimara nke arụmọrụ dị elu, ngwa ngwa ngwa ngwa, nchebe gburugburu ebe obibi ndụ ndụ na enweghị mmetọ, na arụmọrụ dị mma nke workpiece mgbe ọgwụgwọ gasịrị.

Nkà na ụzụ mkpuchi laser bụkwa otu n'ime teknụzụ mgbanwe elu ọhụrụ na-anọchite anya ntụziaka mmepe na ọkwa nke injinịa elu.Teknụzụ mkpuchi laser abụrụla ebe nyocha na ngbanwe elu nke alloys titanium n'ihi uru ya nke enweghị mmetọ na ngwakọta ọla n'etiti mkpuchi na mkpụrụ.Ihe mkpuchi mkpuchi seramiiki nke seramiiki ma ọ bụ ihe mkpuchi seramiiki mesiri ike bụ ụzọ dị mma iji melite nguzogide elu nke titanium alloy.Dị ka ọnọdụ ọrụ n'ezie, họrọ usoro ihe onwunwe kwesịrị ekwesị, na teknụzụ mkpuchi laser nwere ike nweta usoro kachasị mma.Teknụzụ mkpuchi laser nwere ike ịrụkwa akụkụ dị iche iche dara ada, dị ka agụba aeroengine.

Ọdịiche dị n'etiti alloy n'elu laser na mkpuchi elu laser bụ na alloying laser bụ iji gwakọta ihe niile agbakwunyere na ihe mkpuchi elu nke mkpụrụ na steeti mmiri iji mepụta oyi akwa alloying;Laser elu cladding bụ agbaze niile precoating na micro agbaze nke mkpụrụ n'elu, nke mere na cladding oyi akwa na mkpụrụ ihe na-etolite a metallurgical Nchikota na-eme ka ihe mejupụtara nke cladding oyi akwa isi agbanweghị.Laser alloying na laser cladding technology bụ nke a na-eji eme ihe iji melite nguzogide iyi elu, nguzogide corrosion na nguzogide grading nke alloys titanium.

Ka ọ dị ugbu a, a na-eji teknụzụ mkpuchi laser eme ihe n'ọtụtụ ebe na nrụzi na ngbanwe nke elu igwe.Otú ọ dị, ọ bụ ezie na omenala laser cladding nwere uru na àgwà nke nhazi mgbanwe, nrụzi pụrụ iche, onye ọrụ-akọwapụta mgbakwunye, wdg, ọrụ ya arụmọrụ dị ala, na ọ ka na-enweghị ike izute chọrọ nke nnukwu-ọnụ ọgụgụ ngwa ngwa mmepụta na nhazi na. ụfọdụ ubi mmepụta.Iji gboo mkpa nke mmepụta oke ma melite arụmọrụ nke mkpuchi, teknụzụ mkpuchi laser dị elu bịara.

Teknụzụ mkpuchi mkpuchi laser dị elu nwere ike ghọta oyi akwa mkpuchi enweghị ntụpọ.Ọdịdị elu nke oyi akwa mkpuchi bụ kọmpat, njikọta metallurgical na mkpụrụ, enweghị ntụpọ na-emeghe, na elu dị larịị.Ọ bụghị nanị na a ga-edozi ya na ahụ na-emegharị ahụ, kamakwa na ụgbọ elu na elu dị mgbagwoju anya.Site na njikarịcha teknụzụ na-aga n'ihu, enwere ike iji teknụzụ a mee ihe na coal, metallurgy, nyiwe dị n'ụsọ osimiri, imepụta akwụkwọ, ngwa obodo, ụgbọ ala, ụgbọ mmiri, mmanụ ala, ụlọ ọrụ ikuku, wee bụrụ usoro nrụpụta akwụkwọ ndụ akwụkwọ ndụ nke nwere ike dochie teknụzụ elektrọn ọdịnala.

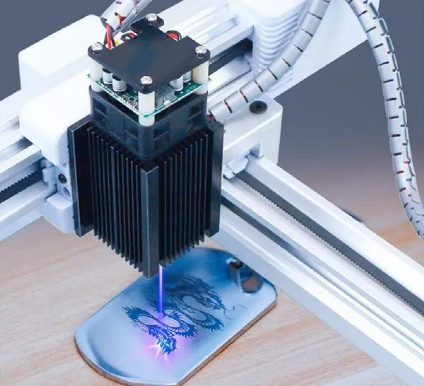

7. Laser osise

Ihe osise laser bụ usoro nhazi laser nke na-eji teknụzụ CNC na-emepụta ọkụ ọkụ laser dị elu n'elu ihe onwunwe, ma na-eji mmetụta okpomọkụ nke laser na-emepụta iji mepụta ụkpụrụ doro anya n'elu ihe.The anụ ahụ denaturation nke agbaze na gasification nke nhazi ihe n'okpuru irradiation nke laser osise nwere ike ime ka laser osise nweta nhazi nzube.Ihe osise laser bụ iji laser kanye okwu n'ihe.Okwu ndị teknụzụ a pịrị apị enweghị nicks, elu nke ihe ahụ dị larịị ma dị larịị, a gaghị eyikwa ihe odide aka.Njirimara ya na uru ya gụnyere: nchekwa na ntụkwasị obi;Kpọmkwem na nlezianya, nkenke nwere ike iru 0.02mm;Chekwaa nchedo gburugburu ebe obibi na ihe n'oge nhazi;Ọsọ ọsọ dị elu, ihe osise dị elu dị ka eserese mmepụta;Ọnụ ala dị ala, ejedebeghị site na ọnụọgụ nhazi, wdg.

8. Laser 3D obibi

Usoro a na-anakwere teknụzụ mkpuchi laser, nke na-eji laser mee ka ikuku ntụ ntụ na-ebufe na-agbaze ozugbo ihe dị mfe ma ọ bụ ntụ ntụ ntụ.Mgbe eriri laser gachara, mmiri mmiri ahụ na-agbake ngwa ngwa iji ghọta ngwa ngwa prototyping nke alloy.Ka ọ dị ugbu a, a na-eji ya eme ihe n'ụdị ụlọ ọrụ mmepụta ihe, nrụpụta igwe, ikuku ikuku, agha, ihe owuwu, ihe nkiri na telivishọn, ngwa ụlọ, ụlọ ọrụ ọkụ, nkà mmụta ọgwụ, nkà mmụta ihe ochie, omenala na nkà, ọkpụkpụ, ọla na ubi ndị ọzọ.

9. Ahụkarị ụlọ ọrụ mmepụta ihe nke laser elu ọgwụgwọ na remanufacturing

Ka ọ dị ugbu a, a na-ejikarị ọgwụgwọ laser na teknụzụ mmepụta ihe, usoro na akụrụngwa eme ihe na metallurgy, igwe Ngwuputa, ebu, ike mmanụ ala, akụrụngwa akụrụngwa, ụgbọ okporo ígwè, ikuku ikuku, igwe na ụlọ ọrụ ndị ọzọ.

10. Ngwa nke teknụzụ electroplating laser

Laser electroplating bụ nkà na ụzụ ọhụrụ na-eme ka ọkụ eletrik dị elu, nke dị oke mkpa maka mmepụta na ịrụzi ngwaọrụ microelectronic na nnukwu sekit jikọtara ọnụ.Ka ọ dị ugbu a, ọ bụ ezie na ụkpụrụ nke laser electroplating, laser ablation, plasma laser deposition na laser jet ka na-eme nyocha, etinyere teknụzụ ha.Mgbe laser ma ọ bụ pulse laser na-aga n'ihu na-eme ka elu cathode dị na bat electroplating, ọ bụghị naanị na a ga-eme ka ọnụọgụ nke metal dị mma nke ukwuu, kamakwa enwere ike iji kọmpụta ahụ chịkwaa trajectory nke eriri laser iji nweta mkpuchi na-enweghị mkpuchi nke igwe. echere mgbagwoju geometry.

Ngwa nke laser electroplating na omume na-adabere na njirimara abụọ ndị a:

(1) Ọsọ na mpaghara irradiation laser dị elu karịa ọsọ electroplating na ahụ (ihe dị ka ugboro 103);

(2) Ikike njikwa nke laser siri ike, nke nwere ike ime ka akụkụ dị mkpa nke ihe na-eme ka ọ dị mkpa nke ígwè.Nkịtị electroplating na-ewere ọnọdụ na dum electrode substrate, na electroplating ọsọ na-adị nwayọọ, n'ihi ya, ọ na-esiri ike ịmepụta mgbagwoju anya na ezi ụkpụrụ.Eletrọnkị laser nwere ike ịhazigharị oghere laser ka ọ bụrụ nha micrometer, wee mee nyocha enweghị mkpuchi na nha micrometer.Maka imewe sekit, nrụzi sekit na ntinye mpaghara na ihe njikọ microelectronic, ụdị nkewa ngwa ngwa a na-aghọwanye ihe bara uru.

E jiri ya tụnyere electroplating nkịtị, uru ya bụ:

(1) Ngwa ngwa nkwụnye ego, dị ka ọla edo laser ruo 1 μ M / s, ọla kọpa laser ruo 10 μ M / s, akwa ọla edo laser jet ruo 12 μ M / s, ọla kọpa laser jet ruo 50. μ m/s;

(2) Ngwunye igwe na-eme naanị na mpaghara irradiation laser, na mkpuchi mkpuchi mpaghara nwere ike nweta ya na-enweghị ihe nchebe, si otú a na-eme ka usoro mmepụta ahụ dịkwuo mfe;

(3) Adhesion mkpuchi na-eme ka ọ dịkwuo mma;

(4) Mfe ịghọta akpaka akara;

(5) Chekwaa ọla ndị dị oke ọnụ ahịa;

(6) Chekwaa itinye ego na oge nhazi akụrụngwa.

Mgbe laser na-aga n'ihu ma ọ bụ laser na-akpali akpali na-eme ka elu cathode dị na bat electroplating, ọ bụghị nanị na a ga-eme ka ọnụọgụ nke metal dị mma nke ukwuu, kamakwa kọmputa nwere ike ijikwa usoro mmegharị nke eriri laser iji nweta mkpuchi na-enweghị mkpuchi na mgbagwoju anya a na-atụ anya ya. geometry.Teknụzụ ọgbara ọhụrụ nke laser jet emelitere electroplating na-ejikọta teknụzụ elektrọnik laser emelitere yana ịgbasa ngwọta electroplating, nke mere na laser na plating nwere ike gbaa n'otu oge gaa na cathode elu, na oke mbufe oke dị ngwa karịa ọsọ mbufe oke. nke micro-akpali akpali nke laser irradiation kpatara, si otú a na-enweta ọsọ ọsọ nke nkwụnye ego dị elu.

Ọdịnihu mmepe na ihe ọhụrụ

N'ọdịnihu, mmepe ntụziaka nke laser elu ọgwụgwọ na mmakịrị n'ichepụta akụrụngwa nwere ike ichikota dị ka ndị a:

· Ọrụ dị elu - nhazi nhazi dị elu, izute ngwa ngwa mmepụta ngwa ngwa nke ụlọ ọrụ ọgbara ọhụrụ;

· Ọrụ dị elu - akụrụngwa nwere ọrụ dịgasị iche iche, arụmọrụ kwụsiri ike ma dị mma maka ọnọdụ ọrụ dị iche iche;

· ọgụgụ isi dị elu - ọkwa ọgụgụ isi na-akawanye mma mgbe niile, na obere aka aka;

· Ọnụ ala - ọnụ ahịa akụrụngwa na-achịkwa, na ọnụ ahịa ihe oriri na-ebelata;

· Nhazi – nhazi akụrụngwa ahaziri onwe ya, ọrụ ire ere,

· Na mgbakwunye - ijikọta teknụzụ laser na teknụzụ nhazi ọdịnala.

Oge nzipu: Sep-17-2022